Water

A&F Co. has implemented water stewardship and conservation practices in our operations and across our supply chain.

Goals

Reduce water intensity in denim production: 30% by 2028

A&F Co. partnered with denim laundries and mills to reduce water intensity in their operations by 31% in fiscal year 2023 compared to a 2019 baseline.

Use recycled water (increase the amount of water being recycled in both denim laundries and mills): 50% by 2028

A&F Co. partnered with denim laundries and mills to increase the amount of water recycled in their operations by 20% in fiscal year 2023 compared to a 2019 baseline.

Strategies

Supply Chain

Garment manufacturing uses a great amount of water, particularly the drying and washing processes. We work with our denim suppliers to implement new technologies, equipment and water-saving methodologies. In 2021, we conducted a survey to all denim washhouses against industry water best practices and provided them with guidance to identify water-saving opportunities.

Examples include using trigger guns, low-flow and shutoff valves to turn off hoses in washing areas when not in use and using e-flow technology to reduce chemical and water consumption in wash process.

Global Home Offices, Distribution Centers & Stores

A&F Co. works to increase water efficiency where possible in our direct operations. To limit water and energy use, home office teams combine wash loads across brands to sample home launder testing.

And our home office utilizes an automated irrigation system for landscaping to optimize water distribution. Our new and remodeled stores receive low-flow toilets and faucets.

Other Key Focus Areas

Chemicals

A&F Co. requires its suppliers to properly use, store and dispose of chemicals in the manufacturing process. Our Vendor Code of Conduct specifically requires suppliers to adhere to our Restricted Substance Policy and Restricted Substance List. View our Restricted Substance List.

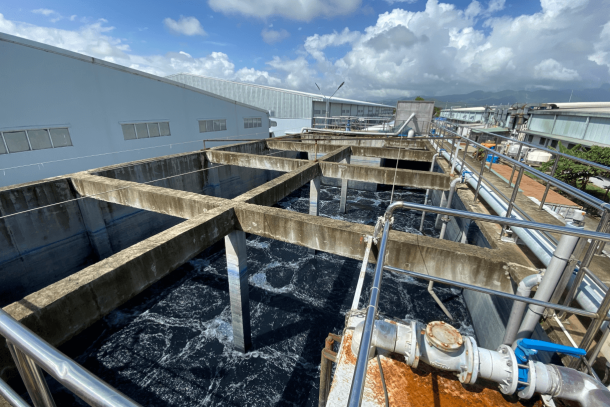

Recycled water

In 2023, A&F Co. expanded its corporate goals to aim for 50% recycle water use in our denim laundries and mills by 2028. We partner with our suppliers to upgrade their existing wastewater treatment, including installations reverse osmosis (RO) systems to improve the wastewater treatment quality and recycle the treated wastewater.

Compliance with Local Laws

A&F Co. continues to help build the vendors’ capabilities in monitoring to reduce environmental impact to the greatest extent possible and comply with all relevant local laws and regulations including proper use and management of chemicals, hazardous and non-hazardous waste disposal, wastewater, water quality, energy use, GHG emissions and recycling. In particular, the adoption of Higg FEM by our suppliers helped to develop robust environmental management system (EMS), and/or put a plan in place to document current permits, and/or records as required by local law. As part of our annual social audit, an A&F Co. designated third party will assess compliance with environmental permits, including compliance with wastewater discharge permits.

Wastewater

We require our denim washhouses to use the Zero Discharge of Hazardous Chemicals (ZDHC) guideline to ensure discharged wastewater is not polluting the environment. According to the ZDHC Wastewater Guidelines version 2.1, this includes 23 physical and chemical parameters (e.g., temperature, Chemical oxygen demand (COD), 15 heavy metal and 20 chemical groups on the ZDHC MRSL (Manufacturing Restricted Substances List). In 2021, A&F Co. wastewater test program covered all denim washhouses and garment dyehouses. Beginning in 2022, A&F Co. expanded the program to our key fabric mills. The purpose of testing is to ensure discharged wastewater from washhouses is not polluting the environment.

A&F Co. appointed a ZDHC approved laboratory to collect wastewater samples and conduct the test annually in all denim washhouses and garment dyehouses. Factories’ level of conformance will be rated based on the test results. Factories need to submit a corrective action plan if any parameters are detected exceeding the limit. We will also work with suppliers at risk to identify improvement opportunities, particularly on their chemical management systems.

Measuring Our Progress

Water Reduction

Our denim washhouses use Jeanologia’s Environmental Impact Monitoring (EIM) software to measure water consumption per denim. Jeanologia is the first tool specifically created for the garment industry to measure the impact of laundry and finishing processes. Since 2019, when A&F Co. set a goal to reduce water usage in denim production, we have saved over 190,300,000 gallons of water with more efficient dying and washing methods.

In 2023, A&F Co. refresh the water reduction goal to reduce water intensity in the operation of denim laundries and fabric mills by 2028 in compared to 2019 baseline. We partner with our facilities to develop their water reduction plans in alignment with some of the industry best practices such as process and wastewater reuse, cooling water reuse and use low material liquor ratio (MLR) washing machines.

Wastewater Compliance

In addition to the wastewater test program, we continue to build the vendors’ capabilities in monitoring to reduce environmental impact to the greatest extent possible and comply with all relevant local laws and regulations including proper use and management of chemicals, hazardous and non-hazardous waste disposal, wastewater, water quality, energy use, GHG emissions, and recycling. As part of our annual social audit, an A&F designated third party will assess compliance with environmental permits including compliance with wastewater discharge permits. Further, the adoption of Higg FEM by vendors has helped to develop robust environmental management system (EMS), and/or a plan in place to document current permits, and/or records as required by local law. With the continued partnership with our vendors, the Higg FEM EMS and Wastewater score improved by 45% and 54% in Higg FEM, respectively, since 2018.

As part of our annual social audit, an A&F designated third party will assess compliance with environmental permits including compliance with wastewater discharge permits.

In 2023, a total of 118 facilities completed ZDHC wastewater testing with 97% compliance.* This includes 100% of our denim washhouses and garment dyehouses and 71% of fabric mills by production volume.

*Compliance refers to test results that meet ZDHC Heavy Metals Wastewater Parameters and Limits, Table 2 and Conventional Parameters and Anions for Wastewater, Table 3 according to ZDHC Wastewater Guidelines Version 2.1.